Pneumatic Globe Valve

Pneumatic Globe Valve

Nominal: PN1.6 ~ 4.0MPa

Body Material: WCB, ZGlCrl8Ni9Ti, ZGlCrl8Ni2Mo2Ti, ZG00Crl7Nil4M02 , ZGlCr5MO

Suitable Medium: water, oil, steam, nitric acid, phosphoric acids, bases, mixed acid, urea, ammonium carbamate solution

Temperature: 200 ~ 550 ℃

First, The Exhaust Valve

Pneumatic globe valve with double acting cylinder, the use of the upper chamber intake or the lower chamber into the long-distance control valve, easy to operate and flexible. Simple structure, easy to manufacture and maintain; work stroke is small, opening and closing time is short; closed body (valve) and the valve seat sealing surface with a tapered seal, close the force small, resistant to erosion, sealed and reliable. Seat for the replacement valve seat, can be any combination with the closure of the sealing surface material matching to meet the working conditions, to extend the service life.

Second, Structure Features

1, Selection of sophisticated, in line with domestic and foreign relevant standards, reasonable structure, handsome in appearance.

2, The valve, the valve seat sealing surface with iron-based alloy surfacing or Stellite (Stellite) cobalt-based hard alloy surfacing, wear, high temperature, corrosion resistance, scratch resistance, long service life The

4, Stem and quenched and tempered surface treatment, a good corrosion resistance and scratch resistance.

5, Can be used in a variety of piping flange and flange sealing surface type to meet the needs of various projects and user requirements.

6, The full range of valve material, packing, gasket can be based on actual conditions or user requirements reasonable matching, can be applied to a variety of pressure, temperature and media conditions.

7, Inverted seal with a threaded connection Seal or body welded austenitic stainless steel, sealed and reliable, replace the filler can be carried out in the case of non-stop, convenient and quick, does not affect the system operation.

Third, The Implementation Of Standards

Design and Manufacture | GB / T1223 | |

Connection Size | Structure Length | GB / T12221 |

Flange Size | JB / T79 | |

Inspection and Testing | JB / T9092 | |

Material | Carbon Steel | GB / T12229 |

Stainless Steel | GB / T12230 | |

Alloy Steel | Q / ZB6 | |

Fourth, The Main Parts Of The Material

Body | Cap | Discs | Sealing Ring | Stem | Filler | Applicable Media | Applicable Temperature (≤ ℃) |

WCB | WCB + D507MO | D577 | 2Crl3 | Flexible graphite | Water, Oil, Steam | 425 | |

ZGlCrl8Ni9Ti | 0Crl8Ni9Ti | Stellite6 | lCrl8Ni9Ti | PTFE | Nitric Acid | 200 | |

ZGlCrl8Ni2Mo2Ti | CF8M | lCrl8Ni2Mo2Ti | lCrl8Ni2Mo2Ti | PTFE | Phosphoric Acid, | 200 | |

ZG00Crl7Nil4M02 | CF3M | Stel1ite6 | 316L | PTFE | Phosphoric Acid, | 200 | |

ZGlCr5MO | ZGlCr5MO | Stel1ite6 | 25Cr2Mo1VA | Flexible Graphite | Water, Oil, Steam | 550 | |

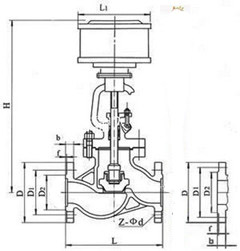

Fifth, Main Connection Ssize

Nominal Pressure PN (MPa) | Nominal Diameter DN (mm) | Standard Value | Reference | |||||||

L | D | D1 | n2 | b | f | Z-φd | L1 | H | ||

1.6 | 50 | 230 | 160 | 125 | 100 | 16 | 3 | 4-φ18 | 185 | 645 |

65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-φ18 | 232 | 690 | |

80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-φ18 | 232 | 715 | |

100 | 350 | 215 | 180 | 155 | 20 | 3 | 8-φ18 | 232 | 770 | |

125 | 400 | 254 | 210 | 185 | 22 | 3 | 8-φ18 | 283 | 780 | |

150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-φ23 | 283 | 810 | |

200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-φ23 | 283 | 967 | |

250 | 622 | 405 | 355 | 320 | 30 | 3 | 12-φ25 | 283 | 1143 | |

300 | 698 | 460 | 410 | 375 | 30 | 4 | 12-φ25 | 283 | 1292 | |

2.5 | 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-φ18 | 185 | 645 |

65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-φ18 | 232 | 690 | |

80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-φ18 | 232 | 715 | |

100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-φ23 | 232 | 770 | |

125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-φ25 | 283 | 780 | |

150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-φ25 | 283 | 810 | |

200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-φ25 | 283 | 967 | |

250 | 622 | 425 | 370 | 332 | 36 | 3 | 12-φ30 | 283 | 1143 | |

300 | 698 | 485 | 430 | 390 | 40 | 4 | 16-φ30 | 283 | 1292 | |

4.0 | 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-φ18 | 185 | 645 |

65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-φ18 | 232 | 690 | |

80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-φ18 | 232 | 715 | |

100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-φ23 | 232 | 770 | |

125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-φ25 | 283 | 782 | |

150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-φ25 | 283 | 875 | |

200 | 600 | 375 | 320 | 282 | 38 | 3 | 12-φ30 | 283 | 1160 | |

Zhejiang public security reserve No. 33032402001552

Zhejiang public security reserve No. 33032402001552